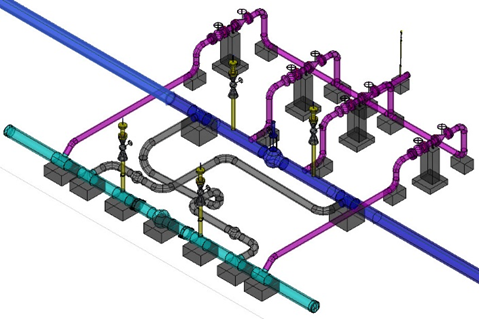

Our engineers have experience designing virtually every type of pipeline project, from new pipeline installations to facility improvements. We handle all design services from initial planning to final design, including measurement, regulation, flow control and gas processing. We can also provide construction oversight.

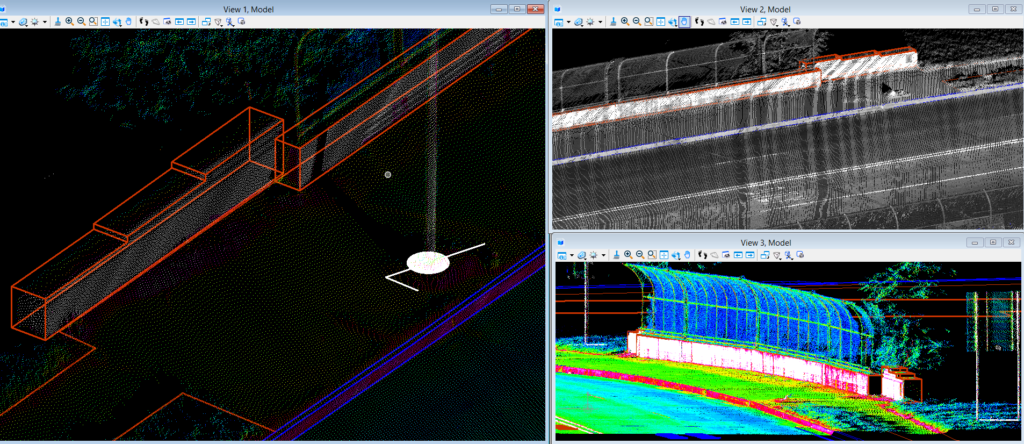

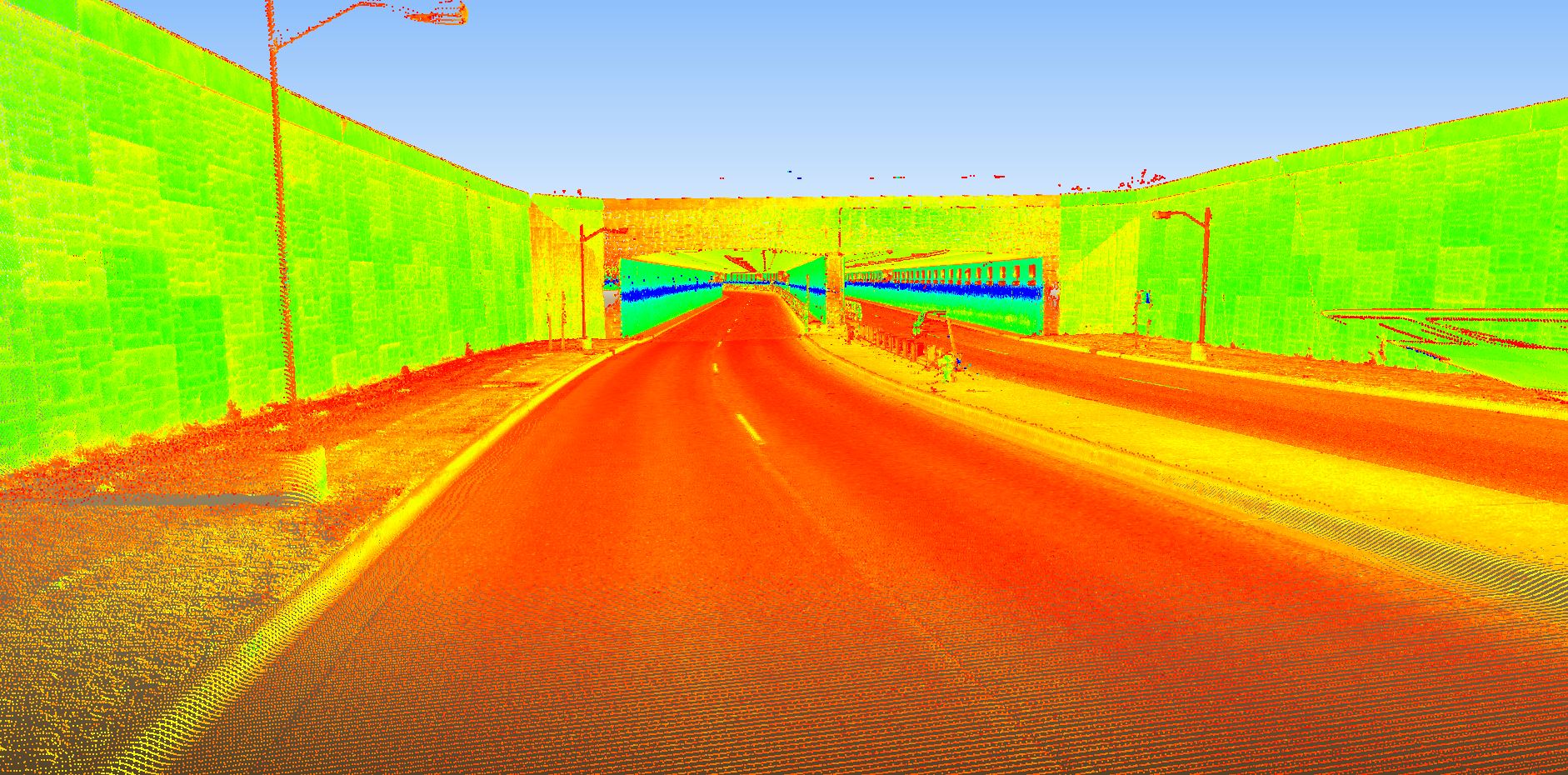

In response to advancing technology in the? survey and design fields, HEI has advanced software and trained professionals? that can model existing and proposed mechanical systems in a 3D model. By laser scanning existing stations, our designers work in a real-world model to ensure the highest level of accuracy compared to conventional methods. This approach also enables HEI to handle design changes more efficiently.

In response to advancing technology in the? survey and design fields, HEI has advanced software and trained professionals? that can model existing and proposed mechanical systems in a 3D model. By laser scanning existing stations, our designers work in a real-world model to ensure the highest level of accuracy compared to conventional methods. This approach also enables HEI to handle design changes more efficiently.

Our skilled HDD designers have extensive experience coordinating with state and federal agencies and working around US Army Corps of Engineers levee systems. Coordinating with a drilling contractor where necessary, they will identify appropriate product pipe and determine the optimum drill path to meet both your requirements and industry guidelines. After installation, they can perform operational stress analysis.

Other services include:

Other services include:

- Coordinating with geotechnical firms to obtain appropriate soil information.

- Full survey services, such as sonar mapping for large water crossings.

- Drilling mud calculations to identify potential inadvertent return locations.

- Providing complete calculation report as well as detailed plan and profile.

Our team of structural engineers is exceptionally qualified to address your specific project needs. We offer a full range of services, including pipeline, vessel and equipment foundation designs, pipe trestle design, plant structural analysis and design and pipe stress analysis.

Using industry standard platforms such as AutoCAD and MicroStation, our drafting staff offer services ranging from detailed project design and construction drawings to tailored drafting. We also use Blue Sky Software, which provides automated mapping capabilities and enables easy extraction of project data for transfer to your GIS system.

Our team of OpQual Certified field personnel are experienced in all phases of integrity management. We offer assistance with HCA classification, pipeline inspection prioritization and cost estimating for facility modification, in-line inspection assistance, planning for hydrostatic testing facilities and close interval surveys for direct assessments.

We also offer post-inspection services, including reviews of inspection tool data, assistance with locating and excavating anomalies, anomaly evaluation, collection of site samples, pipeline repair recommendations and data entry of inspection results.

ILI projects use a tool known as a pig to perform maintenance and inspection operations. The tool is launched into the pipeline and “tracked” at road crossings to verify its location and speed. Smart tools are used with Above Ground Boxes (AGM) to correlate collected data with location so that when a problem (such as corrosion or a dent) is found, the defective pipe can be excavated, inspected and repaired.

Holland Engineering has been providing ILI-related services since 2003 to clients such as El Paso, TransCanada, Great Lakes, Northern Border, Wolverine and DTE.

Our tracking services include reviewing alignment sheets and other resources to determine the best AGM locations, creating survey/tracking spreadsheets, staking and surveying AGM locations, creating GPS files for tracking tools, and tracking cleaning, gauge and smart tools. Our primary service area covers Michigan, Wisconsin, Illinois, Indiana and Ohio. We provide pigging services in the Dakotas, Iowa, Kansas, Kentucky and Tennessee.

We also provide dig services, including preliminary and final staking of the dig area, inspection of the pipe and as-built survey of the pipe.